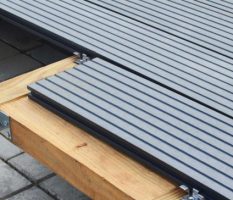

Decking - 110 photos of the terrace board and an overview of the most popular materials and design options

At any dacha, there are two or three places where it would be appropriate to equip level decorative grounds, on which there would be no dirt and weeds. It is too expensive and difficult to lay out such terraces with stone or cobblestone. It is easier and less expensive to make a coating of wood.

But such a flooring will not be durable - due to moisture and the sun, it will quickly lose its pristine properties and rot. As a result, experienced landscape stylists prefer to use decking.

Decking Definition

Decking is a modern building material used to create a patio and to equip a territory near a pond. Also quite often it is used as a floor covering of verandas and terraces.

Nowadays, decking is understood as a terrace board. Another name for decking is decking. Indeed, outwardly such a coating resembles a ship deck.

Decking

Decking allows you to fashionably decorate the local area, beat the plot near an artificial reservoir, decorate the picnic area. The photo of decking shows that it is divided into the following types:

From array

This kind of decking is considered the progenitor of building materials of this type, since it was it that caused the deck board to grow in popularity. Decking from the massif is an ordinary board, which is made of solid wood of pine, cedar, oak, ash.

For those who love something exotic, a variation of tropical trees is suitable. The flooring made of wood species growing in African, Asian and South American forests will look truly exclusive. The amazing fiber structure and long, up to 80 years, operation time give this decking uniqueness.

A great solution would be a mahogany massrandub board. It is distinguished by its resistance to humidity and the possibility of application in a situation with intense loads. A high level of rubber resins prevents the growth of molds.

Kekatong (Australian walnut) coating is durable and stable. These properties are of great importance when designing areas located in the open air. This type of wood is used in shipbuilding, as it can withstand even sea water.

This type of material has the following advantages:

- moisture resistance;

- durability;

- strength;

- naturalness.

- aesthetics.

The solid wood board is resistant to environmental influences and has a beautiful natural texture. Its only negative is the need for systematic care using special formulations - wax, impregnation, oils. The cost of such decking is not small.

From thermal wood

This type of decking is obtained using a special technology of wood processing - high temperature steam treatment. As a result, the moisture contained in the tree evaporates, and it acquires high aesthetic and strength properties. Wood becomes moisture resistant - even direct interaction with water will not lead to its swelling and decay.

It also increases its resistance to sunlight - thermal wood does not dry out and retains its shape. In addition, steam treatment gives it a bright, evenly distributed color and a clear texture that lasts for a long time.

From wood-polymer composite (WPC).

From the name you can judge the composition of the material used to create the details of the coating. A similar board can withstand any climate. This is the most modern kind of decking. Wood-polymer composite is a mixture of fine sawdust and special plastic additives. As a result of such a combination, a material is obtained that has all the advantages of natural wood in the complete absence of its disadvantages.

Plastic decking does not require special care. It feels wonderful in any weather, is not afraid of humidity and the sun, is not deformed from the load.

WPC decking does not burn and fungi are not afraid of it. Because of its advantages, polymer boards are widely used by landscape designers.

Unfortunately, she has also disadvantages. First of all, this is the unnaturalness of a wood-like surface. Also in some cases, there may be swelling, waves and chips. This is typical for products manufactured by unscrupulous manufacturers.

To distinguish low-quality products, just look at the side cut - if air bubbles or foreign inclusions are visible on it, then you have low quality decking.

The most significant disadvantage is the tendency of the KDP boards to deflection. Because of this, in the manufacture of the construction of the site, the distance between the lags should be minimal. And you also need to provide a ventilation system to ensure air exchange of the space under the coating. Stagnation of air masses can lead to mold.

WPC boards can be polished and not polished. These two species have no external differences and they have the same performance characteristics.

Sizes of a terrace board

Depending on the thickness of the decking board there are:

- Thin (1.8-2.2 cm).

- Medium (2.5-3 cm).

- Thick (4.2-4.8 cm).

The width of the deck board varies from 9 to 25 cm. The length can be 3, 4 or 6 m. For the design of small areas, tiled WPC decking is performed with section sizes ranging from 0.25 * 0.25 m to 0.5 * 0, 5 m

Additional expenses when installing decking

If the installation of a natural board requires additional expenses in the form of self-tapping screws, then end parts are needed for laying decking decking. They perform both practical and aesthetic tasks.

As the edging, F and L-shaped profiles are usually used, the edging strip and the jumper strip between the coating and the wall of the building.

Processing the flooring with special protective compounds is necessary during its installation, and then once every two years. The result is a significant amount.

Speaking of supporting racks for flooring, they can be made:

- Made of wood. Laying step - 60-100 cm (depending on the log section). The tree must be dry, humidity should not exceed 25% - otherwise deformations may appear. Processing protective specials. drugs required.

- From the composite. The layout step is 0.3-0.4 m. Such lags are recommended to be used when installing the flooring in difficult weather conditions, but at low loads. When mounting between the surface of the soil or concrete and the uprights, it is imperative to install tight rubber pads.

- From aluminum. Such logs are distinguished by minimal thermal expansion. Suppose installation in increments of up to 1 m. Metal racks cost a lot, so they are used mainly in important areas that require a responsible approach.

We make flooring from a terrace board ourselves

Do-it-yourself decking must be installed on a flat, solid surface.A good option for concrete foundations is adjustable racks that allow you to adjust the height and slope during the construction of the terrace area.

Coating boards, as well as deck decking, must be installed, taking into account all the recommendations of the manufacturer. There are two ways of laying - seamless and with a compensation gap of 4-6 mm between the individual parts. It is important to observe the slope of the flooring of 1.5-2% in the direction of the mounted boards.

Terrace board can be used not only for the construction of decorative areas, but also for wall cladding. Facade decking today is no less popular than decking decking. For its manufacture, KDP is also used.

A platform made of beautiful decking will undoubtedly become an adornment of your summer cottage. Therefore, do not spare the time and effort to erect it.

Decking Photo

Hair cutting - tips and rules for trimming hedges (95 photos)

Imitation of a bar - 130 design photos + DIY installation instructions

Join the discussion: