Do-it-yourself warming the house with mineral wool - a step-by-step instruction with photos and videos. Pros and Cons of Material

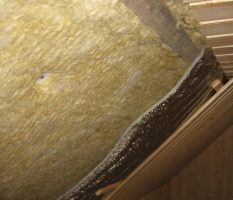

The construction of your own home at a certain stage raises the question for the builder about the need for wall insulation. Thermal insulation work is an important undertaking, since non-compliance with the technology can lead to large heat losses, dampness, fungus and mold.

The service of warming private houses with mineral wool has become more and more popular recently in connection with the realization that after all installation work and putting the structure into operation, you can start to save quite a lot on heating.

The advantages of insulated walls

High-quality thermal insulation works allow achieving high comfort indoors, achieving the desired level of heat and maintaining it for a long time. In the winter months, mineral wool prevents the cold air from cooling down the walls.

In addition, due to the increase in wall thickness and due to its heat-conducting characteristics, it is possible to achieve a shift of the so-called dew point beyond the wall material (for example, to the same insulation). Thus, the life of the building can be significantly increased.

In summer, thermal insulation functions differently: it does not allow the walls of the house to heat up intensely, creating conditions for a constant temperature. Due to this, the house becomes cool (compared to the street).

The facade of the house, insulated with mineral wool, and a well-thought-out ventilation system of the rooms will allow to avoid dampness, the development of mold and fungi, the presence of which adversely affects human health.

Installation of a new heating system, high-quality windows with double-glazed windows in several chambers, as well as doors will complement the list of necessary steps to create optimal housing.

Varieties of mineral wool

The market of building materials is saturated with a variety of insulation, among which mineral wool occupies a separate place. On the network you can find a huge number of photos of home insulation with mineral wool. The raw materials for its production determines the type of cotton wool itself. It can be stone, slag or glass.

Stone wool is made from basalt, granite or porphyrite. Volcanic rock gives a high result in terms of quality and durability of materials made on its basis.

Slag wool is produced from waste from the metallurgical industry. The material is slightly inferior to the leader, because it does not cope with sudden temperature changes in late autumn and early spring.

In addition, the increased humidity from the steam passing through the wall material to the outside reduces its life. Often this variety of mineral wool is used to warm shed buildings, garages.

Glass wool is obtained by mixing waste from glass production, soda, limestone, dolomite and drill mineral. The material is elastic and resistant to vibrations. As a rule, glass wool is used in structures requiring a high degree of fire safety.

The form of mineral wool production is in the form of plates of various sizes and in rolls. If the heat-insulated surface is large, then use a roll insulation, which reduces the number of joints.

Mineral wool has a different degree of hardness, which is marked on the packaging. Soft cotton wool is used indoors, for example, to create heat and sound insulation of partitions. Rigid and medium hardness is more suitable for walls and roofing pie.

The nuances of warming the house

If a decision is made with your own hands to insulate the house outside with the help of mineral wool, then you need to keep in mind some features of this process. The frame for the installation of mineral wool boards is made of wooden blocks or a metal profile.

Moreover, the distance between the carriers should be made slightly less than the width of the plate itself, so that when it is tightly installed there are no gaps. The latter will be cold bridges that increase heat loss.

The frame should also consist of horizontal bars in order to avoid increased load of plates on each other and their subsequent sagging. You can use special dowels such as "Mushroom".

The dowel itself, passing through the thickness of the insulation, goes inside the wall material. Its large head holds the insulation. A nail (metal or plastic) is driven into the dowel body, expanding it. Thus, the entire structure is securely fixed to the wall.

After mounting the plates, the stage of creating a vapor barrier begins. The membrane is placed in horizontal stripes and starts from the top of the structure. The insulation material can be fixed with a construction stapler if the carriers are made of wood.

It makes sense to use double-sided tape when applying a metal profile. The main thing to remember is that the membrane must be overlapped (about 10 cm, or along the corresponding line on the material itself), and the joints must be glued with a special tape.

The next step involves installing the crate on top of the vapor barrier. This is done for those reasons that a ventilation gap should remain between the insulation and the facade.

The vapor from a person’s life, passing through the wall, the insulation and the membrane will dissipate just in the gap space. Thus, a ventilated facade is arranged.

A mounting option is possible on special U-shaped suspensions used for mounting a metal profile under drywall. On the mushroom expansion bolt shield plates or strips from a roll heater are mounted. The density of the material allows the suspensions to pass through the insulation.

Next comes a vapor barrier, and then a metal profile is attached to the protruding ends of the suspensions. It is a supporting structure for the facade and at the same time creates a ventilation gap.

Thus, mineral wool insulation technology is not too complicated, however, elementary building skills are required.

External walls and their insulation

Experienced builders are advised to insulate the house outside. Due to this, heat will be retained in the premises, and cold air will be delayed by the insulating layer. In addition, this option will save usable floor space. There are two ways to insulate the facade: wet and dry.

Wet method. The insulation is mounted on the wall, finishing work is carried out on top of it, for example, plastering. The thickness of the insulating layer is about 10-15 cm.

Plates are glued to the wall with a special glue, additionally fixed with "Mushroom" dowels. After this, the base must be reinforced with a special mesh and plastered with the same adhesive composition.

Facade plaster, for example, bark beetle, completes the decoration. It will perform two functions - protective and decorative. It is advisable to carry out all work in dry weather, since a heater wet from rain will dry for a long time.

Dry method. This method allows you to get the so-called ventilated facade. The insulation is placed between the supporting frame made of timber. The latter is necessarily covered with an antiseptic.

Next is a layer of vapor barrier membrane and crate, on which the facade itself is mounted. In this way, you can insulate the house with mineral wool outside for siding.

If all the technology is followed, then as a result it will be possible to get the facade of your own house, which is reliably protected from atmospheric precipitation, wind and cold. And this is the key to a comfortable stay for the whole family.

Photo of warming a house with mineral wool

A blind area around the house - 110 photos of ideas for creating a blind area with your own hands

Rolled lawn: 90 photos of application in design and laying technology

Polycarbonate greenhouse - 120 photos of purchased and homemade options

Platform for a car: 60 photos of ideas for building from the best materials

Join the discussion: