Front stucco molding - a review of the species (100 photos). Description of all advantages and disadvantages + installation instructions

People have been decorating their homes for a long time. Forging, facade stucco molding, wood carving have not lost their relevance today. And this is not surprising. The facade of the house is considered his face, which means that a lot will tell about the owner, his preferences, financial situation.

Original stucco patterns have been known for a long time. Now they are again a fashion trend. Stucco molding for the transformation of the facade is preferred, both in the design of residential buildings and administrative buildings.

Ancient and modern

Technologies in the field of construction do not stop improving. Building materials that are no longer relevant replace new ones. An area such as facade decoration is not deprived of them.

Today stucco molding looks no less attractive and original, meets the necessary quality standards for similar materials for facade cladding.

Gypsum, as well as marble, is perfectly replaced by artificial building material, characterized by a high degree of resistance to the negative effects of nature. It perfectly withstands ultraviolet, cold, precipitation.

Plaster decor for the facade

Practicality, originality, traditions are the main characteristics of stucco made from plaster. Due to the convenience and simplicity of working with this material, you can get a variety of volumetric exclusive details.

The facade is decorated with stucco made of a material such as gypsum, directly on the wall surface, or in the workshop, with further installation at the location.

For this purpose, ordinary gypsum is used, intended for the manufacture of sculptures, or hydrophobic, which prevents the penetration of moisture. Hydrophobic gypsum has a special composition, so this material has a higher price. It is characterized by increased moisture and frost resistance.

According to professionals, working with this material is not difficult if you have the required forms and accessories. Gypsum is excellently restored, while the design of the architectural purpose will last for a long period of time. This is a fact verified over many years. A variety of cracks and defects it is enough to cover up every five years with a plaster special composition.

There are several disadvantages of gypsum material. One is a big mass. For this reason, it is not advisable to install gypsum parts on structures erected from lightweight structures. Another is the possibility of a split in the event of an accidental fall, which provides for extreme accuracy in the process of installation of the material.

Installation of products from the original facade stucco molding is carried out using dowels, special adhesive mass and nails.

Stucco molding from expanded polystyrene, and also made foam polyurethane

The main difference between expanded polystyrene and polyurethane is its low weight, which makes the installation of finished products much easier. Stucco is held on a special adhesive composition, which is why it is great for buildings that are built from lightweight modern materials.

The front decor is polyurethane does not fear moisture, does not lose color, does not break. In addition, polyurethane has a thermal insulation function. However, the disadvantage of stucco molding is that substances harmful to health are released during the combustion process.

When creating decorations for the facade from cellular polystyrene foam, a machine is used to cut the desired shape and size of the elements. After that, glue, the necessary mesh, another layer of glue, and also paint are applied to them.

The listed types of stucco molding are much more practical and more expensive in comparison with the plaster option, however, foams are not capable of repeating the exclusivity and expressiveness of plaster decorations.

The disadvantages include a low degree of resistance to ultraviolet radiation, as well as the impossibility of restoration work in the event of cracks.

Concrete

The original decor for the facade of concrete is created from polymer concrete, or from an equally well-known material such as fiber-reinforced concrete. The most reliable material in this group is polymer concrete.

In this embodiment, the binder is a polymer. Polymer-concrete stucco molding is characterized by a high degree of frost resistance, attractiveness of the pattern, maximum strength, and durability.

Fiberglass

Beautiful houses with stucco made of fiberglass, very attractive, withstand excessively high and extremely low temperature conditions. The material is made from quartz fibers, fiberglass, as well as thermopolymers.

The price of a fiberglass facade ornament is very high, however, among analogues it is one of the best options, because it is better in characteristics than they are. Among the minuses - the impossibility of creating delicate elements.

When choosing facade decorations, it is important to decide what is more important - the originality of the picture, durability or value. However, in any version, the stucco molding will successfully decorate the outer side of the housing, add volume and solemnity to the facade.

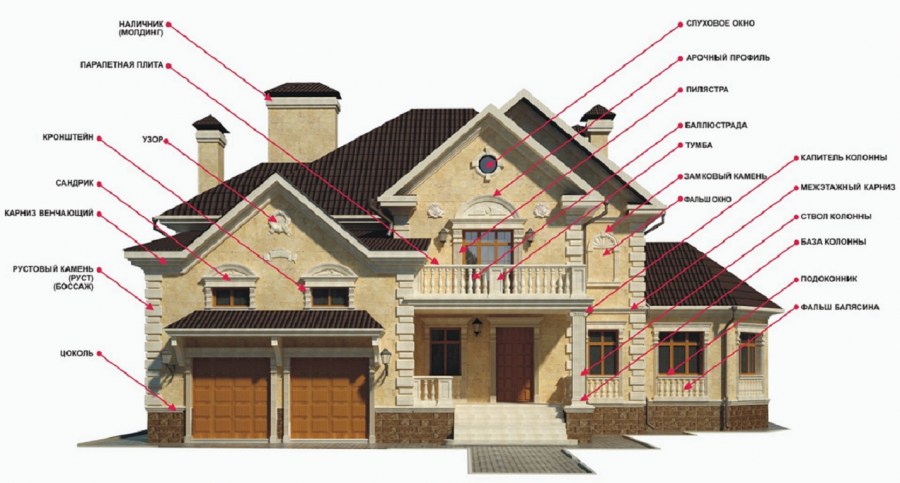

Varieties of stucco molding

Depending on the purpose, the moldings for facade design are divided into such types as:

Columns as well as pilasters. Often installed at the entrance, on open large balconies. During installation, they are urged to abut against the upper-lower surface, in rare cases they are equipped with suspended ones. For installation, it is preferable to consult a specialist.

Arches. Window openings and doors are decorated with similar elements, as in the photo of the stucco molding below. Not a difficult variety of stucco molding, so the installation can be carried out by hand.

Bas-reliefs. Mounted above the door leaf at the entrance, they are used as the design of the facade wall surface of the second floor. Work can be done with your own hands, as it does not require professional skills and a lot of time.

Handrails. They are installed next to the front door. This type of stucco molding is created exclusively from concrete, while the details of the foam and gypsum are not used on the facades.

Stucco molding

First stage. Choose which facade stucco works best for the facade of your home and decide on its future location.

Important! When choosing the style of design of the wall surface of the facade, consider not only decorative indicators, but also the characteristics of the walls. In the case when the facades are not very reliable, it is better to prefer a light foam stucco material, if the walls are made of brick, then you can use any stucco molding. It is installed exclusively on facade brick or plaster.

Second phase. Prepare the facade surface, cleaning it from dust. If necessary, you need to align the wall using a trowel with plaster. The denser the roughness of the wall surface under the stucco molding, the stronger the adhesion will be.

The third stage. Mark the work surface. After applying the necessary markings, inspect the wall again, checking the accuracy of the lines.

The fourth stage. Tighten the parts without stopping, as a rule, these are ebbs of windows. The following parts will be held directly on them to give the structure maximum strength. So that when the glue dries, the stucco molding does not fall, make additional stops in the form of ordinary nails.

The fifth stage. Measure the cornice from below, then saw off the desired ends. Styrofoam stucco is sawn well with a simple hacksaw. If you have an electric saw, work will move much faster.

Sixth stage. To decorate the house with stucco facade, with your own hands, prepare a special adhesive composition, following the advice of the manufacturers specified in the instructions.

Seventh stage. Using a spatula, apply the mixture to a wall surface and stucco. If it’s hot outside, then dampen the wall with water.

The eighth stage. Firmly attach the material to the wall, then remove the protruding adhesive mass using a spatula. It is important that the bottom of the material does not slide down.

The ninth stage. Attach the top side of the decor to the surface, while noting the cut areas.

The tenth stage. In the same way, prepare the side elements.

Eleventh stage. Align all the parts by pressing them as tightly as possible. Eliminate the surplus that has appeared.

Twelfth step. To give the fastener maximum strength, fix the material in several areas using dowels.

Photo of stucco molding

Mineral wool mineral insulation: 90 photos + step-by-step instructions for beginners

Planter for the garden: 70 photos of original ideas using different materials

Flower pots: 65 photos of the most amazing design options

Test for a true gardener - go and get an assessment of your knowledge

Join the discussion: