Water well - drilling pattern, operating principle and selection of the optimal device (70 photos)

For improvement of any country economy water is required. It is needed for construction work, for landscaping and just for personal needs.

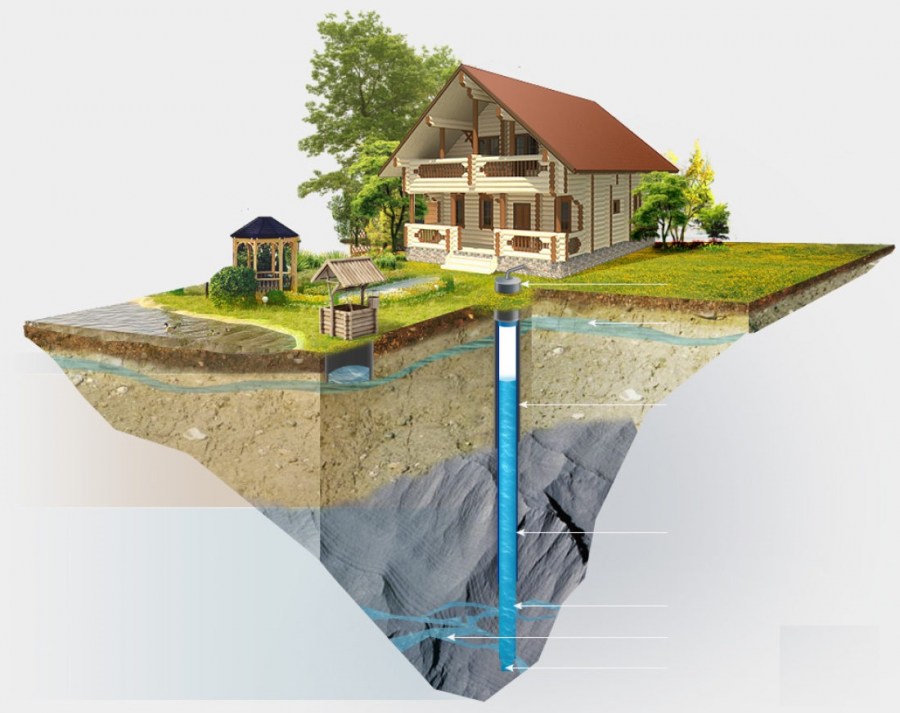

But what if there is no centralized water supply system on the plot? The output will be an autonomously organized facility - a well or a well. The difference between the two is in the depth of the aquifers, the useful life and cost. The preferred option is to install water wells.

Types of wells

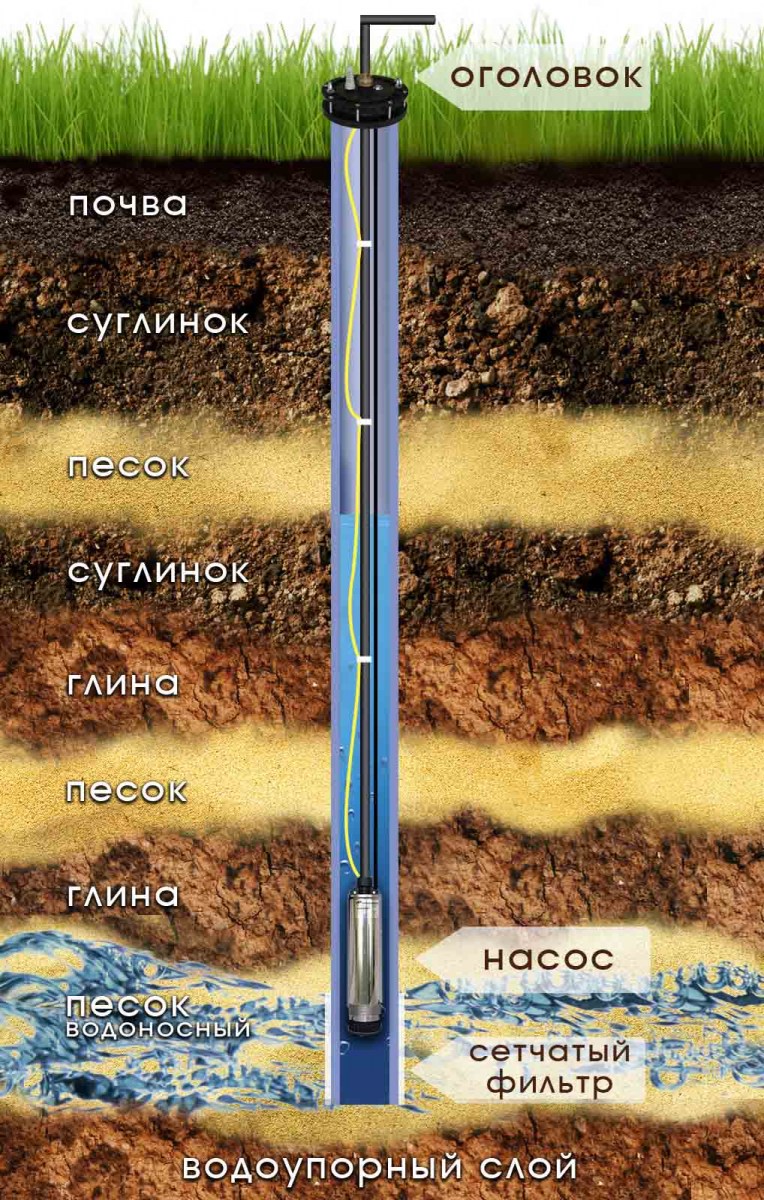

A borehole is a special structure (excavation or cavity in the bowels of the earth) of a cylindrical shape, with a length significantly greater than the diameter.

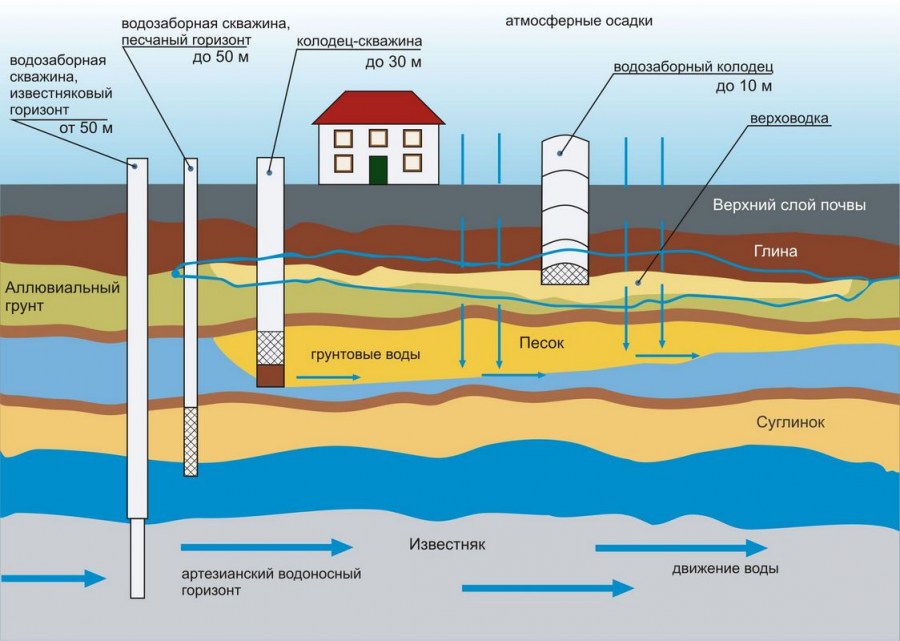

Devices are divided by depth and method of penetration. The depth of the well is determined by the location of the aquifers and the required quality of the fluid. Based on the terrain, aquifers are located in the earth's crust in different ways.

If the landscape is flat, then with a high probability the water lies along the entire perimeter. In the presence of hills, drilling is recommended in the lowlands. The classification of structures contains several varieties.

Abyssinian well

First implemented by British engineer Norton in the 19th century. The maximum depth reaches 10-15m. The design consists of a set of pipes with a diameter of up to 60 mm, which are assembled together by a threaded connection. At the end of the last link is the “needle filter”.

This is a sharp tip that performs several functions: it punches the soil when installing a well and purifies water from large fractions and polluting particles. Installation of the abyssine consists in lifting the pipe with a tripod and driving it into the ground.

The advantages include a compact size, the ability to place in any free zone, ease of maintenance and low financial costs.

The liquid rises forcibly, in the classic way - with a hand pump. A photo of the Abyssinian hammer well is shown below.

Well on the sand

The construction is deepened by 15-40m. The trunk is formed by a pipe with a cross section of 100-180 mm. At its end is a stainless filter element welded to the first link of the drill string. The average life of the product with continuous use is 15 years.

When siltation, contamination of the well, it is washed. If the process does not lead to the desired result, then drilling of a new trunk located near the previous one will be required.

Among the positive aspects, one can single out a democratic price in comparison with an artesian well, a lower content of dissolved iron.

Artesian well (on limestone)

Structurally, it resembles a well on the sand. The main difference is the lack of filter mesh in the lower pipe section and the source depth. Water from such structures comes from aquifers located in the thickness of the limestone. Thanks to what it turns out pure, with a small degree of mineralization.

Advantages:

- Performance. It is able to provide consumers with liquid in a volume of 1 to 3 m3 / hour.

- Continuous water supply. Water loss is not affected by pump runtime. With a five-minute or two-hour mode, the flow rate is the same.

- Bacteriological purity. Artesian layers are practically not affected by pollution from the upper soil layer, sewage.

- Long service life. The operation of the well with one pipe occurs within 20-30 years.When using 2 pipes (plastic is inserted into the iron) it functions up to 50 years.

Only one significant drawback is the high price.

Drilling technologies for different types of wells

Self-drilling of artesian wells for water is a laborious and complex process. It is preferable to use the services of special organizations. Abyssinian and turnkey sand wells are a completely different matter.

The most popular are screw, rotor and shock-rope types of drilling. All of them are made manually or mechanically. Technologies differ in the way the rock is destroyed and recovered.

Auger drilling is considered the most budget option. It is produced using a special screw mechanism - a screw. Rotating, the drill crashes into the soil. Destroyed soil goes to the surface with blades. Limitation of auger drilling - soil type. Only non-hard rocks are well drilled. On stony surfaces, the auger is powerless.

The rotary method will help to drill rock. The tool is a drill pipe, at the end of which a cone bit. Getting rotation from the installation drive, the edges of the bit cut through the soil. The surface of the soil is raised with drilling fluid, which is pumped into the pipe by a pump.

Shock-rope technology is the slowest of all. The bottom line is to use the bailer. It is a piece of pipe with thick walls. On the upper part there is a cutout for extracting soil, and on the lower part there is a ball or flap valve. Hitting the ground, the valve opens and grabs the soil.

Well construction instructions

- Locate the drilling site.

- Prepare tools: drill (auger, chute), winch, rods, pump, shovel and casing pipes. Creating a deep well is impossible without a drill tower. Its height is chosen slightly more than the total length of the bar.

- Dig a pit 1.5x1.5x2m. Protect the walls of such a recess with boards or plywood. The pit is necessary to prevent the shedding of the surface layers of the soil during drilling.

- The assembled drilling tool is mounted vertically and plunged into the ground. Every 50cm. the drill is removed from the earth with a winch and cleaned. Drilling continues until an aquifer is reached.

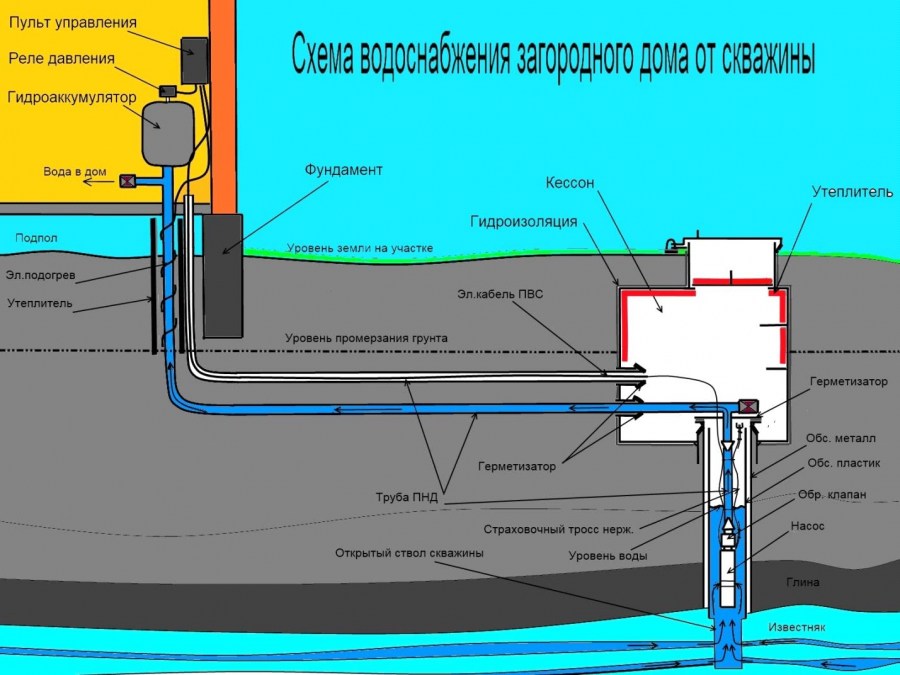

- After detecting the water, casing pipes are installed and a caisson is made. The caisson is a chamber for placement of the pump. A common material for its construction is plastic, brick, concrete or metal.

- Pumping equipment is connected.

Starting work is not very difficult. The drill easily bites into the soil. But with each new dive, the drilling is getting harder. If the drill is stuck and does not rise to the surface, it is recommended to turn it counterclockwise and try to get it.

Choosing a pump for lifting water from a well

The final stage in providing the house with water is its rise from the source. Well pumps are responsible for this.

At the installation site, surface and submersible models are distinguished. The first include devices that work on the principle of suction. They are suitable for wells up to 8m. Surface pumps are a great choice for an Abyssinian well.

This type is not suitable for an artesian or filtration well. Therefore, you must purchase an immersion product. When choosing it, they are repelled from the depth of the well.

The passport of each pump contains data on the maximum height that water can rise.It is better to purchase units with a small margin of performance, i.e. for a 60m well, select a pump designed for a depth of 70m.

An important point is automatic protection against idling. If water stops flowing to the mechanism, but the pump continues to work, this may cause overheating. Automation will turn off the power in time and save the pump from breakage.

By design, centrifugal and vibration pumps are distinguished. In the first case, water is supplied by a paddle wheel, and in the second by an oscillating membrane.

The advantage of vibrating machines is their price, ease of installation and repair. But over time, soil or casing may collapse from vibration exposure. Experts advise considering vibration units as a temporary option.

Safer is a centrifugal pump. It is selected depending on performance, size and maximum working depth.

Photo of a water well

The best flowers for giving: 105 photos of beautiful and simple ideas for the design of the site

Zoning of the site: competent and functional division of the garden (130 photos)

DIY sandbox: 80 photos of phased construction ideas

Chrysanthemum flowers - planting, growing, reproduction and care. (88 photos of chrysanthemums)

Join the discussion: